Portable Equipment

YOKE(HANDY MAGNA)

HANDY MAGNA A1

A1 products use testing method by utilizing the Yoke Method, to magnetize with some or all of test flaws placed between magnet electrodes and detect flaw of the object to be tested by inducting partial linear magnetic field to the test piece.This method enables to easily and rapidly detect surface flaw of forged products or welding, part, etc. As an ultra compact type and ultra light-weight equipment withweight of the main body of 2.1㎏, this product can obtain maximum of efficiency when a worker uses this product for along time, and this product is receiving good response from customers.

- To achieve the best inspection efficiency with small,light equipment

- To form a strong magnetic field with a AC type

- To apply dry, wet and fluorescent magnetic particles

- Excellent durability by using a molding type of rubbermaterial with strong water-proof, shock resistance

- To perform perfect inspection any place such as laboratory, production plant, assembly parts and welding part.

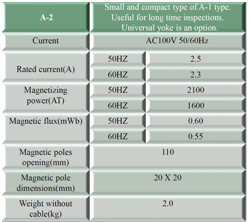

HANDY MAGNA A2:

A2 products use testing method by utilizing the Yoke Method, to magnetize with some or all of test flaws placed between magnet electrodes and detect flaw of the object to be tested by inducting partial linear magnetic field to the test piece.This method enables to easily and rapidly detect surface flaw of forged products or welding, part, etc. A2 is a product with high reliability from customers through continuous R&D and complementation, etc.

- To achieve the best inspection efficiency

- To form a strong magnetic field with a AC type

- To apply dry, wet and fluorescent magnetic particles

- Excellent durability by using a molding type of rubbermaterial with strong water-proof, shock resistance

- To test various objects to be tested by connecting middle poles

- To perform perfect inspection any place such as laboratory,production plant, assembly parts and welding part.

Mobile Equipment

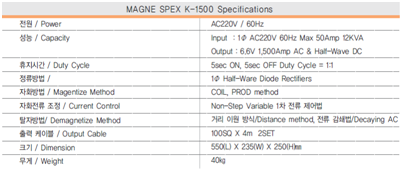

PROD (MAGNETIC DETECTOR) / K-1500

K-1500 is a portable prod detector, manufactured to detect flaws through the circular magnetic field generated while passing direct current by using and contacting the prod to the object to be used, and easily detect flaws within products such as cast-steel products or welding parts with a high magnetic power.

K-1500 adopts magnetization methods such as axial current method, coil method and prod method, etc enabling to detect flaw in the X, Y-direction and rapidly, easily perform test of product, and thus is used for final inspection, incoming inspection, inprocess inspection and maintenance check, etc.

Stationary / HorizontalType

Feature:Heavy industrial parts inspection. There are two contact and coil transformer which can able to use separately. So it is easy to handle many different sizes of work pieces. Save time by magnetizing coil and contact simultaneously.Adjustable tail stock. Push-button, Foot-switch operated pneumatic headstock. Decaying demagnetization. Magnetic particle agitating pump.

Application:Suitable for testing large material such as large crank shaft and block body, and also applied to long material as coils are fed.

Magnetization method:Axle current, coil magnetization and prod magnetization

Model of order :1. MS-3000HCM (2000Amp) 2. MS-4000HCM (4000Amp) 3. MS-5000HCM (5000Amp) 4. MS-6000HCM (6000Amp)

Demagnetizer

This demagnetizer is on the two-way of distance designed tocontrol demagnetization by 0 through 100%. With the

material placed on the supporting table, feed the material forproceeding demagnetization.Setup of the material feed time for demagnetization process.

It is possible to manufacture a demagnetizer depending ontype, size of other material.

– Alternate current demagnetization device: CurrentAttenuation Method

– Direct current demagnetization device : +/- reversion

– Handy demagnetization device: Demagnetize holding thehands for a mobile type.